Avoiding automation rabbit holes

How to prevent running into common automation delivery challenges and misconceptions

This is the second and final blog of this two part series on end-to-end automation projects from Be | Shaping the Future UK’s (Be UK) experience. The focus of this blog will be on the common challenges and misconceptions when delivering an automated solution, in order to provide more awareness of the dangers accompanied with any company considering automation and robotics investments.

It is important that decision makers embarking on automation initiatives remain aware of the barriers to achieve a successful implementation. Around 30 – 50% of automation initiatives fail mainly because businesses do not understand how to implement, use, or manage the technology properly.(1)

What should be taken into account?

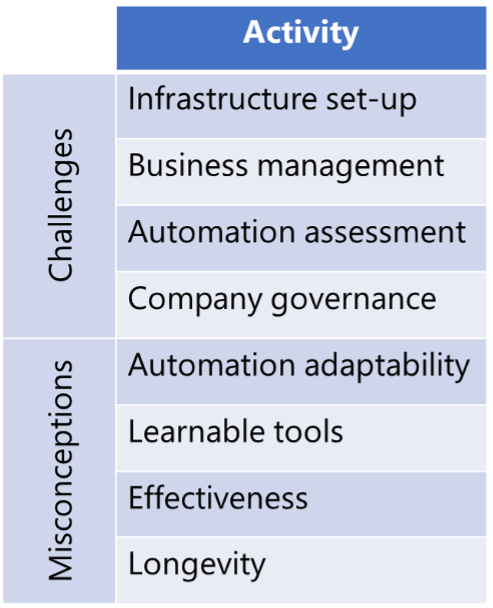

As with all projects, there are always unforeseen mishaps that can occur during the delivery of automated processes. The graphic below highlights the major challenges and stakeholder misconceptions to be aware of.

Common challenges

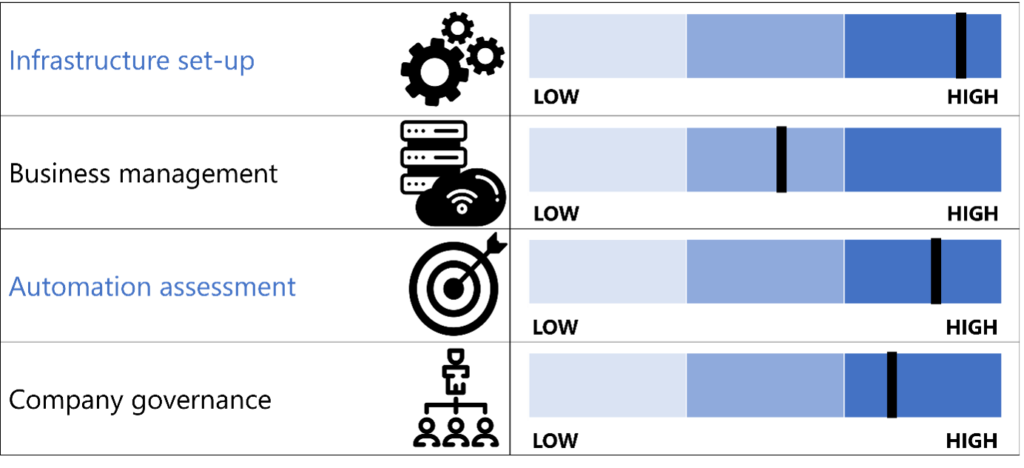

- Infrastructure set-up:

Depending on what tool or technique is being used, you must have a sturdy and robust infrastructure in place to support the solution. Unfortunately, it is common that when a project begins, the optimal virtual machine, database and server configuration is not in place or isn’t available for initiation. This can compromise delivering to time and budget, in addition to affecting processing speeds once the solution is in situ. Therefore, it is crucial to ensure the infrastructure specifications are met from the offset.

- Business management (ownership):

Another area that is often neglected by businesses during the planning stage is consideration for the department in which the automated solution will sit and the individual/s who take ownership of its upkeep. Automation touches both IT and application support, but also has a business dependency as this is where the business logic behind the process originates. Therefore, companies often misjudge the optimal operating model once the solution has been delivered.

It is pivotal from the outset to ensure a group of technically minded individuals are partnered with the business subject matter experts in order to maintain the solution once in production.

- Automation assessment:

As I mentioned in the first blog, a thorough automation assessment of a process is carried out to fully appreciate the cost-benefit of automating, accurately estimate delivery timelines and establish a priority backlog. Frequently businesses fall into the trap of just electing to automate a process that is challenging or time-consuming to perform without running a proper ‘return on investment’ analysis. This can leave the company open to delivering lower than expected business benefits, stunting enthusiasm for future automation initiatives.

- Company governance (access rights):

Automated functions perform the steps that would normally be conducted by a physical full-time equivalent (FTE). This could be physical screen clicks, typing, data manipulation or transformation. For FTEs to perform their work they need access rights to the various password protected systems. This cannot be forgotten in the case of an automated process that will require virtual machine access including its own password credentials and system elevation to carry out tasks. Conversely, it is also important to ensure this virtual worker is governed correctly to ensure the solution falls within the risk and control / policy framework that a human worker would have to abide by.

Decision maker misconceptions

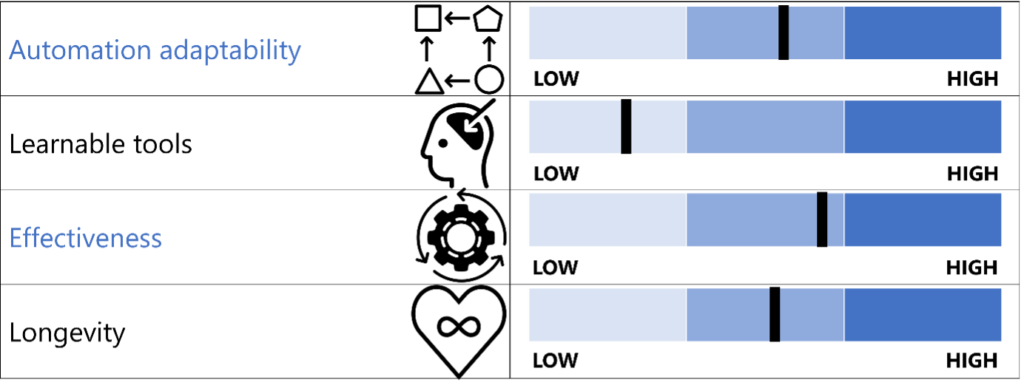

- Automation adaptability:

While robotics and automation tools are very adaptable, capable of working with most software systems and process situations, it should be noted that there are some limitations that decision makers often forget. Any process that requires human decision making and doesn’t follow business rules will not be automatable. Equally, if process data is not in a structured, digital format it will be very difficult to solutionise.

Finally, there are certain virtualised environments that are crippling for automated solutions. Citrix has been known to make recognising elements on a screen very difficult for a robotic solution, so a different method may have to be employed in similar situations.

- Learnable tools:

In the case of robotic process automation, it is assumed that due to the vendor claims that anyone can use these ‘drag and drop – low code’ tools, little to no prior training or basic functional coding syntax knowledge is required to automate business processes. This is untrue in practice as whilst the tool may well be easier to use than traditional code development, technical delivery and testing cycle experience is needed to deliver a fully functioning process.

- Effectiveness:

For true effectiveness, significant care must be taken when choosing what, and at what stage to automate. If the ‘as-is’ process being automated is inefficient and poorly designed, then the automated version will continue to be inefficient, with the only difference being that it is being performed by a line of code rather than a human (GIGO – garbage in, garbage out principle). Process improvement via methods such as Lean Six Sigma or best practice benchmarking should be performed before any automation occurs to deliver the highest value to the end client.

- Longevity:

Finally, many decision makers see automation and robotics as a ‘quick-fix’ to rectify processes or core systems. Once these issues are rectified, by improving the process or replacing a legacy system, many see automated processes becoming redundant or simply being underutilised. This presents a missed opportunity for companies that are not leveraging the technology to provide a lasting benefit. Linking back to the challenges section and the need for a properly conducted automation assessment, the correct processes must be selected and monitored once implemented to prevent the solution becoming redundant, while ensuring business benefits are realised.

Closing remarks

A great innovator of his time, Henry Ford of the Ford Motor Company, once said “the only real mistake is the one from which we learn nothing”. A key takeaway for any business looking to employ new emerging technologies should be to absorb the learnings from previous internal or external project experiences to give their engagement the best chance of success.

The challenges and misconceptions described in this article have been compiled as examples from previous experiences of the consulting team at Be UK, and have been used to strengthen the delivery of many client projects in this area. If you would like to speak to our experienced team about your automation plans for 2022, please get in touch.

Reference: 1) Flowit. (2020). Why RPA projects fail and how to learn from mistakes. [online] Available at: https://flowit.ee/en/rpa-projects-fail/#:~:text=RPA%20projects%20fail%20because%20companies%20and%20those%20who [Accessed 30 Jan. 2022].